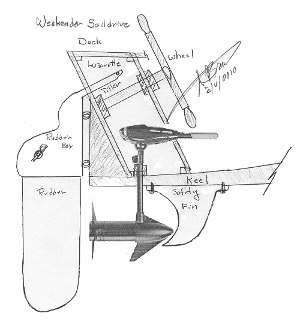

Weekender SailDrive

"A saildrive on a boat is an arrangement of an inboard motor that is about a sailboat's equivalent of a motorboat's sterndrive, also known as an outdrive. The difference is the motor sticks out of the bottom of the hull of the boat, instead of from the stern. It is much different from a traditional inboard motor, as it has no prop shaft. A saildrive resembles the bottom part of an outboard motor; this opts for a smaller arrangement inside the boat, which in turn will create more internal space."

This arrangement can be imitated in a Stevenson's Project Weekender Sailboat with an electric trolling motor and a hole in the bottom & keel. The concept is just mount the trolling motor as you would normally but do it inside the boat, not on the outside.

Concept: I downloaded an image of the Minn Kota Endura 55 with a 42 inch shaft. I used a photo program to shorten the shaft, print the resulting image and then freehand drew around it. Since there are no real dimensions, I guessed at proportions. I then scanned my drawing for the image on the right.

I downloaded an image of the Minn Kota Endura 55 with a 42 inch shaft. I used a photo program to shorten the shaft, print the resulting image and then freehand drew around it. Since there are no real dimensions, I guessed at proportions. I then scanned my drawing for the image on the right.

I knew that I had ordered a motor with a shaft much too long (it was on sale at Walmart) but any motor would have had a long shaft, much too long . The only modification needed on the motor, for the weekender saildrive, would be to shorten the shaft. Of course that requires removing the head and wire connections. The shaft must be cut with a hack saw so be careful to not nick the wires inside then shorten the wires. Locating just where to cut the shaft was a bit of a guess by measuring inside and outside in its desired location, using measurements from the motor as a guide.

Installation:

The other concerns are a slot in the lazarette front to accommodate the handle below the steering wheel and a 1 1/8 inch hole in bottom and keel. The hole cut with a paddle bit and was lined with silicone caulk which filled any gaps or roughness remaining after cutting the hole. Another benefit was that this produced a smooth rotation of the motor shaft as well as sealing the hole from water. Water getting into the lazarette wasn't much of a concern as the hole was about water line with the boat empty and not much below the water line with passengers aboard. There should not be much water pressure to force water into the lazarette.

On the inside, I made an oak washer, three inches in diameter on the outside and for the hole in the middle, 1 1/8 inches, the exact diameter of the Minn Kota motor shaft. I set this in a bed of silicone caulk and held it down with a couple of screws placed fore and aft to drive into the keel. The motor shaft was held in place on the inside with a clamp ring, part of the original mounting for the transom bracket. Then the motor head was mounted on the shaft and rewired per the pamphlet included with the motor.

The small width of the lazarette opening severely limits how far the motor will turn left and right but I didn't expect to use the motor for a lot of cruising in the first place, but mostly at launch and retrieval time. If I need a tighter turn, I expected to use the wheel and rudder as I would without the motor. I considered fixing the motor straight with the keel but that would have been even more "garage engineering" than I thought the idea was worth.

All this was done long before the boat's first launch so it was "theory" not yet proven in the field. I was committed to the idea from the get-go. I knew this arrangement was going to introduce a lot of drag but if speed were an issue, I would not have built a sailboat in the first place. The "sacrificial" protective fin was installed in hopes it would bear the brunt of any damage from grounding. It also introduces a little more lateral resistance at the stern, thus reducing the weather helm just a bit but not enough to notice ... I hope.

Finished Saildrive Installation:

====================================================================================

The First Trial Did Not Work Well!

On our second launch, the motor hit the bottom, opened the stuffing box and it leaked like a sieve. I set to planning a rebuild of the idea of a built-in motor. I considered building it into the rudder but wasn't sure until I ran into a worker at Home Depot who did exactly that. He said is worked like a charm so I set to trying it myself. My efforts were pretty crude but I does work. I also built the speed rheostat into its own box attached to a panel covering the lazarette. Pics below.

====================================================================================

The picture on the left is the rudder/motor in normal or down position. The motor is deeper than it needs to be and the rudder is less long than the plans rudder but is wider, resulting in about the same "water surface" area as originally specified. The lower motor position allows me to swing the rig up and secure it. The image on the right is the travel position. I used a wooden peg through a hole in the rudder box and rudder to secure it in place.

I used some vinyl stick on letters from the local art supplies store and coated the panel with polyurethane to give my installation a finished appearance. The housing seen on the right is a lunch-meat box. I paid the extra to get water proof quick connectors. It works well!

====================================================================================

Well, That didn't work well either.

The rudder was far too big, heavy and introduced a lot of drag. The boat was very difficult to control. So I rebuilt the mount again. I cut down the rudder with the motor embedded, reshaped it and built a hinge mount. Now the problem is that is it too low, below the water line with people in the boat but I refuse to mount it over my wonderful lettering job of the stern. That introduces some drag but I will just leave it that way.

That's enough. I can't rebuild it again.